The vacuum blood collection tube is mainly composed of a test tube, a cap, an inner coating of the tube, a separating glue, a coagulation accelerator, an anticoagulant, etc. The manufacturing quality of each part can affect the quality of blood collection.

1. The quality of vacuum blood collection tube and the method of quality inspection

The basic material requirements for the manufacture of test tubes are relatively high, and they need to have quite high hardness, high transparency, not easy to break, and the lowest possible air permeability and water permeability. Although glass has high transparency and high hardness, it is easy to break. It breaks during blood collection, transportation, and centrifugation, resulting in the loss of blood samples, causing disputes between doctors and patients. At present, it is basically not used.

Chlorinated polyethylene PEC is a material commonly used in the manufacture of test tubes in the past. Its cost is lower and can meet the hardness requirements, but its water permeability and air permeability are higher, and the vacuum attenuation is faster, which not only shortens the shelf life, but also enables the amount of blood drawn. Decrease, especially the anticoagulant tube requires a high degree of accuracy in the amount of blood collected. When the amount of blood collected is reduced, the test result will be seriously affected. At the same time, due to its high water permeability, the water of the anticoagulant added in the test tube will gradually leak out, so that the ratio of the volume of the anticoagulant to the volume of blood will decrease, and the test results will be affected. However, in order to reduce costs, a large number of domestic and foreign manufacturers still use PEC materials to produce test tubes.

Polyethylene terephthalate (PET) is the main material of some high-quality test tubes at present. It is superior to PEC in terms of hardness, air permeability, water permeability, and transparency. It is the mainstream trend of future development. Domestically, such as Shandong Chengwu Medical Products Factory, all test tubes are made of PET materials. Since PET substrates are completely imported and costly, most manufacturers have not yet used them.

Polyethylene naphthalate (YEN) is a better material for test tubes found so far. Its hardness and transparency are close to glass, and its water permeability and air permeability are extremely low. However, due to its high cost, it is currently not produced.

2. Intimal coating of blood collection tube and method of quality inspection

The thin coating inside the test tube is mainly to prevent the blood from directly contacting the tube wall, enhance its smoothness, and improve the compatibility of the blood with the test tube wall. The coating on the tube wall is mainly 16-18 carbon-based materials, and the inner coating materials used are also different according to the different uses of the test tube. Conventional anticoagulant-free serum tubes are coated with 16 carbon alkyl groups, which are negatively charged, which can induce platelet aggregation and release, and accelerate blood coagulation; heparin anticoagulant tubes are mainly used for plasma detection. The coating material is a mixture of 16-18 carbon alkyl groups, which is basically zero charge, does not affect the blood environment, and can maintain blood stability; provides ethylenediaminetetraacetic acid (EDTA) anticoagulation tube for whole blood test, which can maintain blood The originality of the cell keeps its shape unaffected. Because the surface of red blood cells is negatively charged, the coating material is weakly negatively charged, which keeps the blood cells away from each other and does not aggregate into clusters. If the coating on the inner wall of the tube is not good enough or the coating quality is not good, it can cause the blood to hang on the wall. After centrifugation, there are small blood clotting particles or even blood clots in the tube, which will cause the needle to be blocked during automatic sample injection and insufficient aspiration, resulting in inspection. The result is inaccurate, and even serious problems such as instrument failure and shutdown occur. If the coating material in the EDT A or sodium constitutive tube is positively charged, the blood will be prone to coagulation, which will seriously affect the test results.

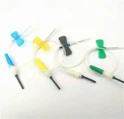

3. Caps and methods of quality inspection

The tube cap must have considerable hardness, be able to seal the test tube tightly, without air leakage and water leakage, and have enough toughness to allow smooth entry and exit of the sampling needle when puncturing the sampling needle, and the needle eye can be quickly closed after the needle is pulled out without leakage of blood or air. , Manual opening and cover are easy to operate, etc. The main base material of the cap is modified heptyl rubber. Appropriate addition of hardness materials such as ceramic powder, etc., makes the degree of crosslinking just right. If the formula is not appropriate, if it is too hard, the puncture will not be smooth, and it will be difficult to open and cover; if it is too soft, it will leak air and water, and the seal will not be tight. Some will also drop chips and block the injection needle, causing serious inspection errors. . In order to reduce costs, some manufacturers use natural rubber or synthetic isoprene-free rubber as the cap material, which has poor purity and is prone to contaminate blood with precipitates, causing errors in test results.

4. The method of separating glue and inspecting quality

Serum will be affected by blood cells during blood placement. For example, when placed for a long time, blood sugar is decomposed by red blood cells, resulting in lower blood sugar; hemolyzed contaminated serum will cause errors in the test results of many items, and blood cells will precipitate or use a lot of enzymes to make it The test result is inaccurate. The function of the separation gel is to separate the serum from the blood cells. After adding the separation gel, centrifuge in time to separate the serum and blood cells, and separate a layer of separation gel in the middle, which can avoid the occurrence of the above-mentioned problems. Separating glue is a thixotropic substance, a mixture of a-olefin anhydrous maleic acid, etc. This substance is an elastomer under normal conditions, and will change when it encounters a certain pressure, high temperature and certain shearing force. The oil body has a specific gravity of 1.05, which is between serum 1.03) and blood cells (1.08). When the blood is drawn and centrifuged, the separating gel encounters pressure and becomes oil body, which is between serum and blood cells. After the centrifugation is over, the pressure disappears and returns to an elastomer, blocking the serum and blood cells. If the quality of the separation gel is not good enough, the molecules will be denatured before the application at a higher temperature. After centrifugation, they will not be able to return to the elastomer state, causing blood contamination and needle blockage, which will affect the quality of the test.

5. Accelerating substances and methods of quality inspection

The role of coagulant is to accelerate blood coagulation and advance the test report time, which is conducive to meeting the requirements of emergency test and current physicians and patients for rapid, high-quality and high-efficiency laboratory departments. At present, most serum tubes are added with a certain accelerator substance. I~3um colloidal stone powder microspheres are one of the coagulant substances. They are sharp, rock-hard particles that can stimulate the aggregation and release of platelets and accelerate blood coagulation, but their particles are larger, similar to the size of platelets. Can puncture red blood cells and cause hemolysis. At present, better manufacturers, such as the domestic Shandong Chengwu Medical Products Factory, use multi-level charge-induced nano-microspheres as coagulant. Its particles are small, the coagulation efficiency is high, and the blood coagulation speed is fast. The particles are round and not Will destroy red blood cells and cause hemolysis.